1. The first water pipes were made from wood

When you walk across Václavské náměstí (Wenceslas Square) or Karlovo náměstí (Charles Square) in Prague consider the 12th century, which is when a system of wooden pipes distributing utility water, but only to church buildings and those owned by the nobility, passed through this area. Don’t be amazed, this information is absolutely correct – the pipes and open troughs were really made of wood. Materials such as stone, fired clay and lead also started to be used at this time.

2. Empress Sisi had the first flushing WC in her chambers

Cast iron pressurised water pipes saw the light of day for the first time in 1660 in Versailles in France. But these pipes were only used to circulate hot water several centuries later, directly to the imperial bathroom of Empress Elizabeth, known under the name of Sisi. It is also interesting that she had the first flushing toilet in her royal quarters.

3. Drinking water was supplied to the people in the 19th century

Efforts to treat water so that it could be used for cooking and drinking culminated in the second half of the 19th century, at the same time Empress Elizabeth enjoyed hot water from her tap. The first drinking water mains were built in Bratislava, in our lands. Technology has advanced since then and today we can be thankful for the opportunities that transportation of water to our homes provides us with.

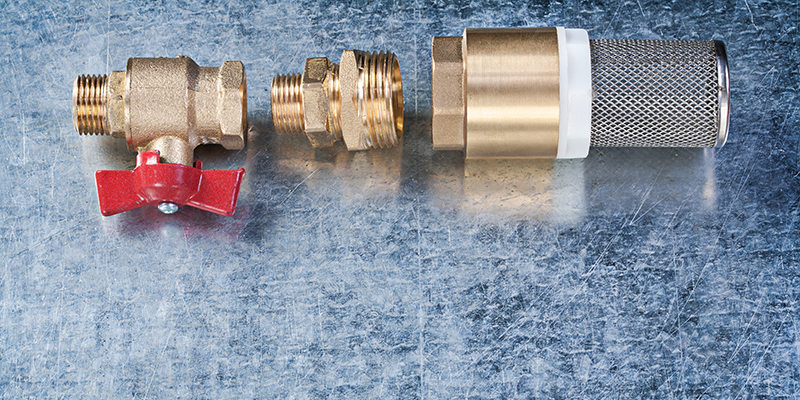

4. Which materials rule the water mains world today?

Wooden troughs are a thing of the distant past. Much higher quality pipes made from various materials circulate our water in today’s world. Strict requirements are placed on this material and it must be high-quality and meet hygienic requirements. In other words, the material used to make pipes for carrying drinking water must ensure that absolutely pure water, which will not harm your health, is supplied to your homes. Let’s look at the requirements the water mains absolutely must meet:

- gas tight, water tight

- safe operation

- hygienically safe

the material must be resistant to test over-pressure, temperature changes and to mechanical damage

This material can do that, another can do something else…

Every application requires a different material used to make the pipes. We will now describe various types of material to you, to provide you with a little more information.

PVC

Pipes made from polyvinyl chloride are mainly used in sanitary applications. This material is suited for watering systems, and house and construction pipes. PVC piping has gained popularity in the spa industry and wherever there are swimming pools. We must point out that PVC pipes are only suitable for supplying cold water. Hot water can disintegrate the plastic over an extended period, which is why a number of municipalities have actually forbidden use of PVC pipes for distribution of hot water.

CPVC

Compared to PVC, cream-coloured or dirty white pipes made from chlorinated polyvinyl chloride are also suited for carrying hot water. If you install them in your own home, always use CPVC compatible adhesive for joining them!

PEX

Now this is probably the most popular type of material, the abbreviated name of which means cross-linked polyethylene. It is used for hot and cold water in households and for underfloor heating, central heating or remote heating networks. PEX pipes have a long service life, are safe, light, non-harmful to health and are not the most expensive. They are resistant to temperatures up to 95 °C, pressure, impact and even to over 300 chemical substances.

There are 3 types of pipe, which have been named according to the technological process used to manufacture them: PE-Xa, PE-Xb, PE-Xc.

Copper

Although copper piping works both above ground and underground, it is better to use it exclusively above ground because it can be affected by some types of soil. The disadvantage of this material is its higher price and more complex installation.

Galvanised pipe

Pipes made from steel or iron galvanised with zinc to prevent corrosion. Even though galvanised pipes are ideal for carrying drinking water safely, you don’t see them very often because they are difficult to install. But they are used during repairs.

The service life of pipes

The water treatment method has a considerable impact on the service life of water and heating pipes. Disinfection technologies have found multiple uses in water and wastewater treatment systems across the continent. This market segment includes chlorination and chlorine dioxide equipment, ultraviolet (UV) light, ozone systems and other technologies. More than 90 % of European drinking water is made safe with the help of chlorine, which disinfects all the way up to the tap. Chlorine in household bleach combats a wide range of microbes in homes, hospitals, swimming pools and restaurants. Chlorination is still the leading treatment method used by water treatment systems to prevent diseases. Chlorine levels sufficient for disinfection have been shown to have a considerable negative impact on material performance in pipe systems.

Put your trust in the professionals

What can we say in conclusion? Possibly only that when building your new house or carrying out investment construction activities, consider which material will be ideal for your requirements and which expert on this matter you should consult so that you not only save money but also obtain the most durable pipes with truly long service life.