ARE YOU READY TO MEET THE NEW REQUIREMENTS FOR TOC and TON?

From 21st March 2021, several changes will be taking place within the European Union to unify the ‘assessment criteria for plastics and other organic materials in contact with drinking water (KTW-BWGL)’

SILON has been working on a special cycle which significantly helps reducing the time required for modification of the hygiene properties of pipes in the autoclave and fulfilment of TOC and TON requirements.

Our goal is for pipes made from SILON material to continue to meet the strictest requirements.

This is why we are working very intensively on reducing migration of substances into water, reducing the total carbon content in water and on odour elimination.

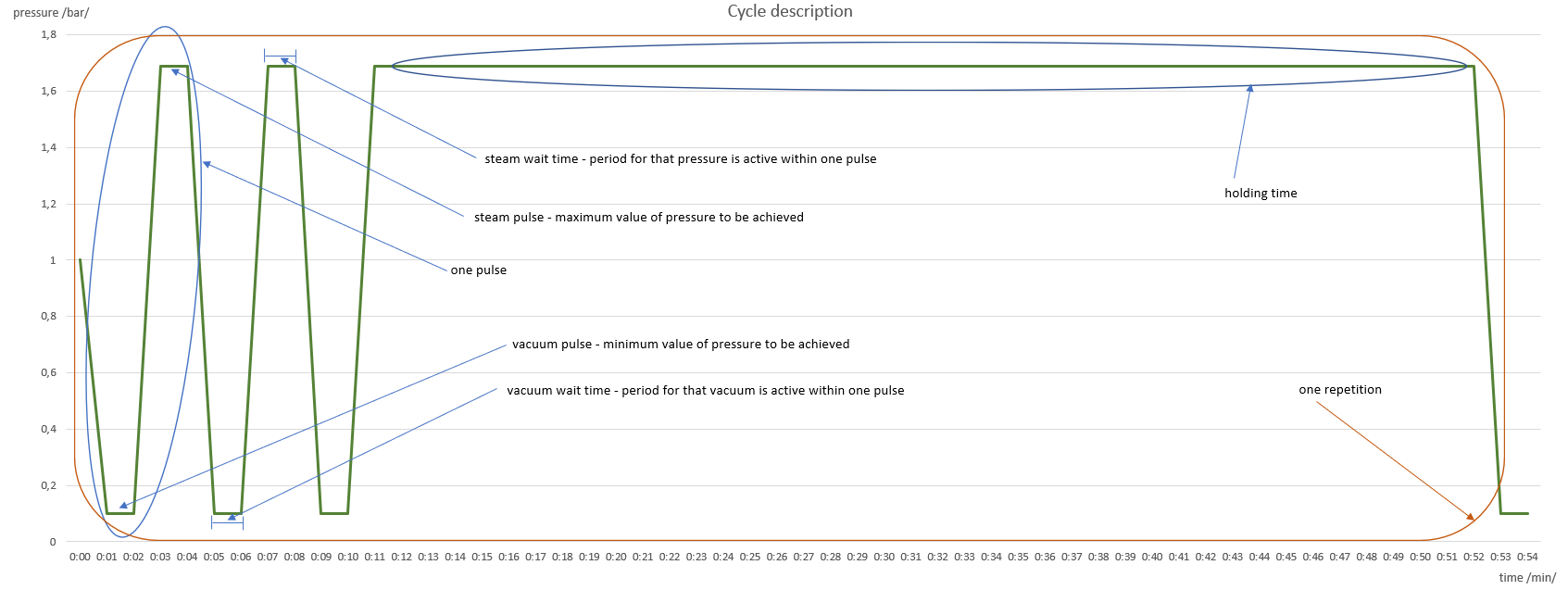

A very important parameter for reducing the time required for treatment in the autoclave

is temperature. An increase in temperature results in an increased rate of reaction. It is therefore ideal to set the temperature in the autoclave to the highest possible value depending on the technical potential of the autoclave and the material composition of the pipes. We used a temperature of 115 °C, which corresponds to a pressure of 1.69 bar, during our tests.

Other parameters contributing towards improvement of the hygiene properties of pipes

- Extension of the Holding time to triple the value

- Extension of the steam waiting time

- Application of a repeated cycle – the Holding phase is not followed by drying, but the entire cycle is repeated again from the beginning (pulses + Holding phase), this process is repeated several times and only then is it followed by the drying phase